Manufacturing

Four Decades of Manufacturing Excellence

Our world-class production facilities, modern infrastructure and streamlined processes are at the core of our success. As India’s second largest fastener manufacturer, STL’s four state-of-the-art manufacturing facilities located at Bangalore, Palwal, Faridabad and Ballabgarh leverage our four-and-half decade strong legacy of precision manufacturing.

Latest technology, machines sources from top global brands and fine-tuned processes implementing Industry-4.0 practices ensure smart and seamless manufacturing. Our dynamic, IT-enabled management including Ebizframe ERP, Statistical Process Control (SPC), LIT, IoT, Scada and QRcode traceability, ensure supply chain efficiency. They give us the agility to manage our largescale operations across multiple locations and expand our volumes and product variety. Precision forging expertise and the policy of zero defect at every stage ensure perfection and durability in every fastener we make.

Largest Fastener

Manufacturer in India

Manufacturing

Facilities

Warehouses

Pan-India

Right from raw material sourcing and inspection, wire drawing, cold forging, thread rolling, heat treatment, surface coating, tooling up till packaging and dispatch, all operations are inhouse giving STL complete control over the quality and full traceability of the final product.

Wire Drawing Plant

At STL, the quest for perfection begins with raw material procurement itself. We source best quality Low carbon, Baron, Medium carbon and Alloy steel from carefully chosen suppliers.

All input raw material is thoroughly inspected using various tests before undergoing the required Pickling, Phosphating, Drawing and Annealing operations at our Wire Processing plant. These finished wires are put through a final inspection to eliminate any surface defects before being sent to our fastener manufacturing facilities.

Cold Forging

Reflecting our cold forging expertise, our facilities are equipped with latest multi-station headers (from 3 to 5 stations) to ensure high productivity, uniform grain structure and better surface finish in our bolts, screws and nuts. Our top-of-the-line Multi station bolt formers, Automatic force sensors and Motorized adjustment systems facilitate smooth and quick setup changes and cover the entire range of M5 to M28 sizes in both standard and special products.

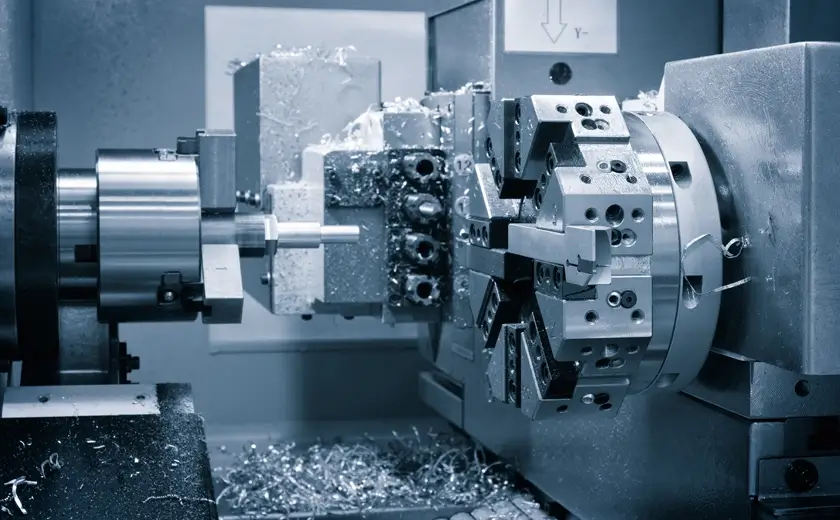

Machining

Our fasteners are also put through various operations such as turning, grinding, facing etc., on CNC and Centerless Grinding machines depending upon the part geometry and requirements.

Thread Rolling

Equipped with latest Flat and Circular thread rolling machines, we ensure perfect lap free threading. We deploy either of these processes alongside our Load sensors, Crocked Thread Sensors and Length+diameter sensors to roll thread onto our fasteners depending on requirement.

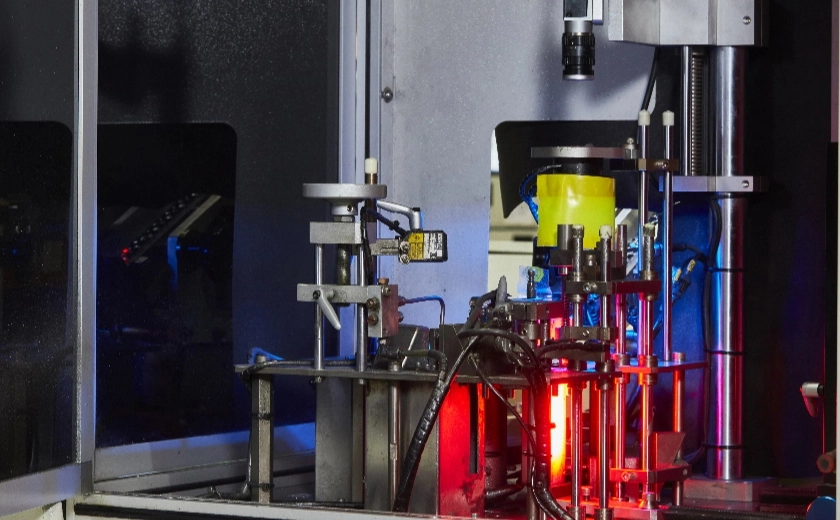

Heat Treatment

Heat treatment is a critical process in fastener manufacturing and our state-of-the-art real-time SCADA controlled continuous heat treatment lines and team of experienced metallurgists ensure the desired mechanical properties in all our products. Our multiple continuous mesh belt type furnaces, Methanol+ Endogas control, Autofeeding by Skako intelligent feeder and astute recipe management ensure that all required heat treatment processes are carried out as per varying grades.

Surface Treatment

Essentially aimed at corrosion prevention, our surface treatments work towards creating durable and low friction finishes that also enhance the aesthetic appeal of our fasteners. Our state-of-the-art surface finishing facilities undertake inhouse surface finishing processes such as Zinc Phosphating, Zinc Plating and Dip Spin Coating and high performance coatings like Geomet and Magni. All our finishing lines are fully automatic and PLC and SCADA controlled. We also offer Online Baking and Passivation including Black Passivation.

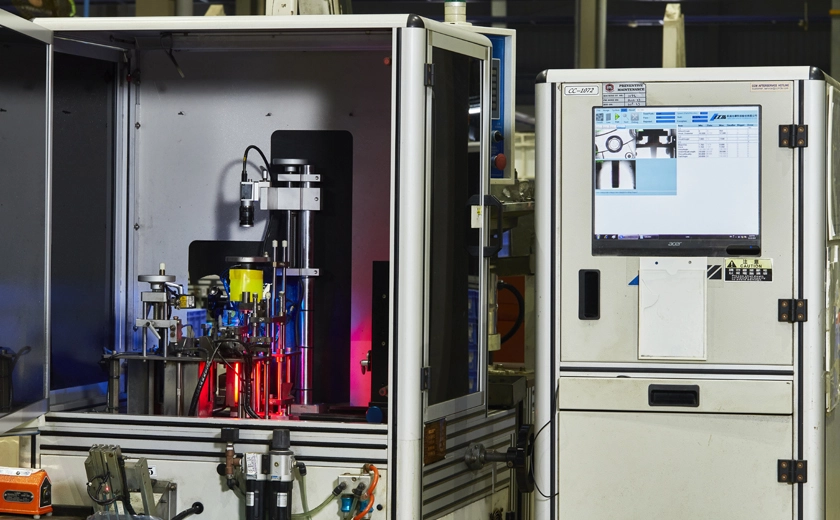

Optical Sorting

Besides the essential Eddy Current testing, STL’s finished fasteners undergo a final inspection using multiple optical sorting machines equipped with multiple cameras to dimensionally inspect all our products. We offer 100% inspection on Sorting M/c (M6, M8 & M10) as per agreed plan with customer.

Packaging and logistics

Packaging is pivotal to ensuring the longevity of our fasteners and the efficiency of our supply chains. Following a final visual inspection for critical parts, the fasteners are labelled and packed as per customer requirement. We ensure weather-proof packaging before dispatching our products to warehouses for on time delivery to our clients.